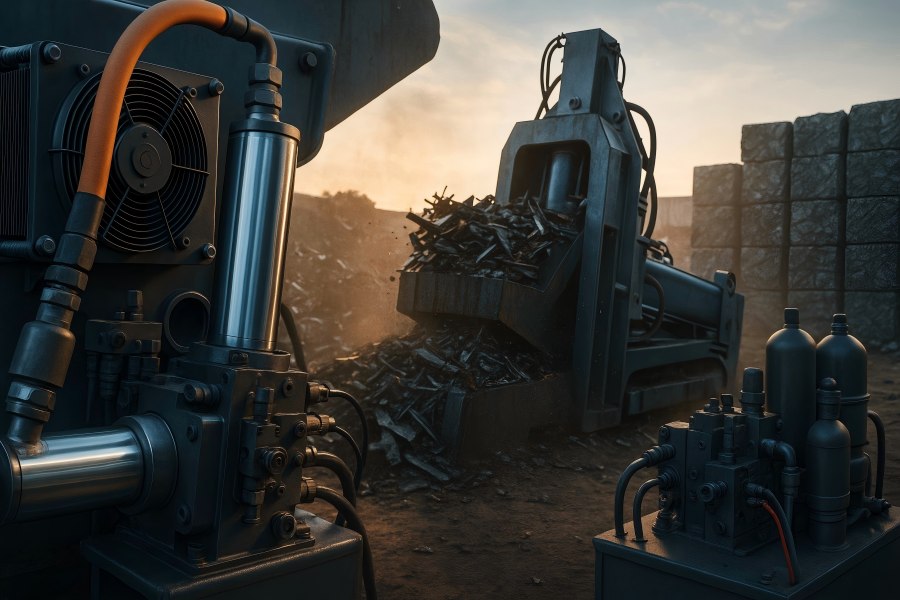

Scrap yards depend on throughput, bale consistency, and uptime. High-performance metal balers use hydraulics to turn motor power into precise, repeatable compaction.

This article explains why hydraulics dominate, outlines a high-performance HPU, and shows how choices in pumps, valves, cylinders, controls, and cooling deliver faster cycles, denser bales, lower energy use, and longer service life.

Why hydraulic power is the natural fit

Extreme force density

Metal balers need hundreds of kilonewtons to multiple meganewtons of ram force to collapse bulky, irregular scrap. Hydraulic cylinders deliver enormous force in compact packages because force scales with pressure × piston area.

Running at 210–350 bar (21–35 MPa) is routine for industrial HPUs, packing press-like tonnage into a footprint far smaller than a mechanical press of equivalent capacity.

Smooth, controllable motion

Oil is nearly incompressible but provides enough compliance for shock absorption. Paired with proportional/servo valves and pressure transducers, hydraulics offer seamless transitions between high-speed approach, high-force squeeze, dwell, and retract—exactly the motion profile a baler needs to maximize throughput without beating itself to death.

Overload tolerance and durability

Relief valves and load-holding devices make hydraulic systems inherently forgiving. When a stray shape presents unusual resistance, pressure simply rises to a setpoint; the system doesn’t stall in a way that endangers the drivetrain. Properly filtered and cooled, hydraulic components run for years in abrasive, outdoor environments.

The core architecture of a high-performance baler HPU

A top-tier HPU is much more than a tank, pump, and relief valve. It is a tightly integrated system designed for energy efficiency, controllability, and serviceability.

Prime mover and pump group

Prime mover: Electric motors (IE3/IE4/IE5 efficiency classes) dominate for stationary yards; Tier 4 diesel engines drive mobile shear/baler/loggers. Variable-speed drives (VSDs) on electric HPUs slash idle losses by scaling pump RPM to the demanded flow/pressure.

Pump type:

- Fixed-displacement gear/vane pumps are robust and inexpensive, but waste energy when throttled for pressure control.

- Variable-displacement axial piston pumps (VDAP) with load-sensing and pressure-flow compensation are the performance standard. They match flow to demand, maintaining a set pressure margin above the highest loaded actuator, which dramatically reduces heat and noise.

- Multiple pump stacks (e.g., a small high-pressure pump plus a larger low-pressure pump) let the controller blend high speed/low torque with low speed/high torque, optimizing each phase of the cycle.

Manifolds and valves

Directional control valves (solenoid, proportional, or servo) route flow to compaction rams, lid cylinders, and shear heads. Pressure controls—relief, sequence, counterbalance, and brake valves—set safe limits, enforce motion order, and hold heavy masses against drift. Proportional/servo valves with onboard electronics enable closed-loop position, speed, and pressure control. On modern balers, this is the key to consistent density and shorter, smoother cycles.

Cylinders and mechanics

Bore/rod/stroke geometry. Cylinder force on extension is F = P × Acap; on retraction, F = P × (Acap − Arod). Designers select bore for peak force, rod diameter for buckling and side-load stiffness, and stroke for chamber volume and approach distance. Cushions at the end-of-stroke protect structures and reduce shock.

Guidance and sealing. Wear rings, rod coatings (e.g., hard chrome with alternate eco-coatings), and high-temperature seals (FKM/HNBR) extend life despite abrasive dust and thermal cycling.

Accumulators

Bladder or piston accumulators store hydraulic energy, shaving peak motor demand and boosting transient flow for the approach or shear stroke. Smart logic charges accumulators during low-load phases and discharges during peak events, reducing installed motor kW and line demand charges.

Reservoir, filtration, and cooling

Reservoir sizing: A common rule is 3–5× rated pump flow (in liters vs liters per minute) to allow de-aeration and thermal stabilization. Filtration. Target ISO 4406 cleanliness of 17/15/12 or better for servo-equipped systems; use high-β offline kidney-loop filters and breathers with desiccant.

Cooling: Air-oil coolers or plate water-oil exchangers keep oil in the 40–60 °C sweet spot (viscosity stable, oxidation slow). A thermal bypass protects against high backpressure during cold starts.

Sensing and controls

Balers increasingly ship with fully instrumented HPUs: pressure transducers at key manifolds, RTDs or NTCs for oil temperature, LVDTs on critical cylinders, and magnetic ring sensors for door positions. PLCs or industrial PCs execute motion profiles, enforce interlocks, and log thousands of cycles for analytics.

Pressure, flow, speed, and force

Hydraulics are about balancing force (pressure × area) and speed (flow ÷ area). A few grounded examples help illuminate design choices.

Example A: Full-force compaction

- System pressure P = 25 MPa (≈ 250 bar).

- Main ram cylinder bore D = 300 mm → cap area Acap = π(0.15)2 ≈ 0.0707 m².

- Peak force F = P × Acap = 25 × 106 × 0.0707 ≈ 1.77 MN ≈ 180 tonf.

This is the high-force squeeze needed to densify heavy ferrous scrap.

Example B: Speed with and without regenerative extension

- Rod diameter d = 200 mm → Arod = π(0.10)2 ≈ 0.0314 m².

- Pump flow Qp = 250 L/min = 0.00417 m³/s.

- Normal extension speed: v = Qp / Acap ≈ 0.00417 / 0.0707 = 0.059 m/s.

- Regenerative extension (rod port tied to cap side): v = Qp / Acap− Arod) ≈ 0.00417 / (0.0707 − 0.0314) = 0.106 m/s (~80% faster), but available force drops to F = P × (Acap− Arod) ≈ 0.98 MN ≈ 100 tonf.

Regeneration is perfect for the approach phase—get to the load quickly—then switch to normal mode for the high-force squeeze.

Control strategies that separate ordinary from exceptional

Load-sensing variable displacement

A load-sensing axial piston pump maintains a set pressure margin (e.g., 15–30 bar) above the highest loaded actuator. When valves throttle, the pump destrokes to reduce flow, minimizing heat and lowering energy per ton versus fixed-displacement pumps.

Closed-loop pressure and position

Pressure control delivers consistent bale density despite variable feedstock by holding a compaction setpoint for a specified time (dwell). Position control improves cycle repeatability and shortens hard stops; the controller decelerates the ram to kiss the target without bouncing the structure.

Adaptive cycle optimization

As the controller logs hundreds of cycles, it learns the tonnage-vs-time signature for different scrap families (e.g., white goods, HMS, skeleton). It can then adapt approach speed, regen cut-out point, and dwell duration to maintain density while trimming seconds from each cycle.

Accumulator-assisted peaks

Charging during retract and idle phases, then discharging during approach or shear cuts, lets the HPU ride through demand spikes without oversizing the motor. This lowers installation costs and reduces grid impact.

Energy use and thermal balance

Energy per ton is a powerful yard KPI. Hydraulics provide several levers to push it down: VSD pump drives, multiple pump staging, regenerative circuits, and smart standby modes. Whatever energy is not converted into mechanical work becomes heat.

Good systems compute heat load and size coolers accordingly, keeping viscosity within the datasheet range of the fluid. Excessive temperature accelerates oxidation, varnish formation, and seal failure; it also erodes the margin on servo spool clearances.

Fluids and contamination control

Fluid selection: For most temperate yards, AW 46 (HLP 46) mineral oil offers a solid viscosity range. In cold climates, HVLP fluids with higher viscosity index improve cold starts. Where fire risk is elevated, HFC water-glycol or HFD synthetic esters provide fire-resistance at the cost of lower lubricity and different seal compatibilities—design accordingly.

Cleanliness targets: Servo-valved systems should target ISO 4406 17/15/12 or cleaner. Achieve this with pressure-line and return-line filtration with high-β elements, offline kidney-loop units for constant polishing, desiccant breathers, and proper flushing during commissioning and after major service. Contamination is the silent killer; most premature hydraulic failures trace to particles and water.

Safety and standards

A high-performance baler must also be a safe machine.

- Hydraulic safety layers include primary and secondary reliefs on each circuit to prevent over-pressure.

- Counterbalance/over-center valves on heavy vertical masses to prevent runaway if a hose fails.

- Load-holding check valves to lock cylinders under loss of power.

- Interlocks tying door/lid sensors to motion enable signals, and pressure-rated hoses and fittings matched to surge conditions.

Designers reference ISO 4413, incorporate risk assessments to achieve PLd/PLe where required, and ensure guarding, signage, and emergency-stop circuits meet local regulations.

Typical performance ranges (guidance values)

| Subsystem / Metric | Typical Range (High-performance Yard Baler) |

| System pressure | 210–350 bar (21–35 MPa) |

| Main-ram flow | 150–600 L/min (staged or variable) |

| Cylinder bore (main ram) | 200–450 mm |

| Cycle time (full compress/retract) | 15–60 s (material-dependent) |

| Bale density (ferrous) | 1.0–1.8 t/m³ (material-dependent) |

| Oil temperature target | 40–60 °C (start interlocks below ~15 °C) |

| Cleanliness (ISO 4406) | 17/15/12 or better with servo valves |

| Reservoir volume | 3–5 × total pump L/min |

These are indicative, not guarantees; actual values depend on frame size, scrap mix, and duty cycle.

Three common hydraulic architectures—trade-offs at a glance

| Architecture | How it works | Strengths | Watch-outs | Best use cases |

| Fixed-displacement pump + throttle control | Constant pump flow; valves meter pressure/flow | Low initial cost, simple | High heat at partial load, noisy, poor energy per ton | Small balers, low duty, limited daily hours |

| Load-sensing variable displacement (VDAP) | Pump maintains a margin above load; flow matches demand | Major energy savings, low heat, good controllability | Requires careful tuning of margin and dynamics | Mid-to-large stationary balers, mixed scrap |

| Servo-hydraulic with accumulators + VSD | VSD controls pump RPM; servo valves close loop; accumulators handle peaks | Fastest cycles, best density repeatability, lowest kWh/t | Highest complexity and component quality demands | Flagship high-throughput lines, premium density specs |

Designing for availability: maintenance, monitoring, and service

Predictive maintenance turns the HPU into a source of truth:

- Oil condition (dielectric constant, particle counts, water saturation) predicts varnish and change intervals;

- Pump health (case drain flow and temperature) catches wear before catastrophic failure;

- Cylinder condition (drift rates and pressure decay during holds) reveals seal leakage;

- Thermal margin (cooler ΔT and fan duty cycles) indicates fouling long before overheating halts production.

Serviceability matters: cartridge-style manifold valves, top-mounted filters with drip-free heads, quick-disconnect test ports, and clear hose labeling collapse MTTR when a component requires attention. Remote access to the PLC/HMI for parameter tweaks and diagnostics is now table stakes.

Motion sequencing in real duty cycles

Chamber preparation: doors open, conveyor or grapple feeds.

- Approach: The main ram extends in regenerative mode at high speed.

- Crush: controller cuts out regeneration and ramps pressure to the compaction setpoint; monitors slope (dF/dt) to judge material collapse.

- Dwell/hold: pressure is maintained for a time or until the displacement target is reached for density.

- Shear or tie: shear head actuates (in shear/baler/loggers) or wires are tensioned; sequences are interlocked.

- Retract and eject: accumulator recharge and cooling opportunistically occur here.

Practical design tips

- Right-size the pressure margin: In load-sensing systems, too high a margin wastes energy and heats oil; too low yields sluggish response. 15–25 bar above the highest load is a typical starting point; tune on site with real scrap.

- Mind the annulus area on retraction: Retraction forces are lower because (Acap− Arod) is smaller; if backpressure rises (e.g., from cooler or long returns), add margin in pump sizing.

- Design for cold starts: Add immersion heaters or warm-up loops that bypass coolers; block orifices that only open once viscosity drops into the operating band.

- Protect against cavitation: Maintain Net Positive Suction Head (NPSH) on pumps with low-restriction inlet plumbing, short suction lines, and properly elevated reservoirs.

- Decouple cooling from duty where possible: Independent electric fans/pumps for the cooler avoid over-cooling or under-cooling when the main pump slows.

Checklist for specifying a metal baler’s hydraulic system

- Force & stroke: Required peak tonnage, ram speeds for approach/crush/retract, and cycle time targets.

- Pump architecture: Fixed vs variable displacement; single vs staged stacks; VSD requirements.

- Valving: Proportional/servo needs; manifold integration; counterbalance and load-holding strategy.

- Energy strategy: Accumulator sizing, regen logic, and standby/idle modes.

- Thermal design: Cooler capacity, ambient assumptions, and cold-start provisions.

- Fluid & filtration: Oil type (AW/HVLP/HFC/HFD), cleanliness targets, offline filtration, breathers.

- Instrumentation: Pressure, temperature, position sensors; data logging; remote diagnostics.

- Serviceability: Access to filters, test points, and manifolds; hose routing; spare kits and training.

- Safety & compliance: Relief settings, interlocks, guarding, and adherence to applicable standards.

- Lifecycle costs: kWh/t projection, maintenance intervals, and the cost of downtime vs component upgrades.