Scrap Metal Baler Manufacturer

- Our metal baler efficiently compresses scrap metals such as steel, aluminum, and copper into compact bundles.

- It is widely used in steel mills, metal smelting plants, and scrap yards, with customized solutions available to suit the specific needs of your industry.

- Manual / PLC Automatic Control

- Wireless Sources / Diesel Engines Power

- 4 Bale Discharge Methods

- Custom Bale Size, Shape, and Accessory Options

- Extrusion Pressure from 63 to 2000 Tons

- Processing Capacity from 0.5 to 20 Tons Per Hour

Our Manufacturing Process

- After receiving customer requirements, our engineers design precise drawings and start production with strict processes to ensure efficient, high-quality results.

Step 1

Raw Materials

- We begin by preparing high-quality raw materials in the workshop's cold work area for precise processing.

Step 2

Sawing

- Materials are cut to required dimensions using industrial sawing equipment, ensuring accurate sizing for all components.

Step 3

Welding

- Core structures and frames are welded by skilled workers to form a solid and durable machine body.

Step 4

Punching

- Punching machines create exact holes and slots in structural parts, essential for accurate assembly and function.

Step 5

Lathe

- Rotating parts and fittings are machined with precision lathes to ensure smooth, reliable operation.

Step 6

Polishing

- Components are carefully polished to remove burrs and improve surface quality, durability, and corrosion resistance.

Step 7

Debugging

- Assembled machines are thoroughly debugged and tested to guarantee a 100% qualified rate before delivery.

Step 8

Shipments

- Each metal baler machine is securely packaged and shipped in optimal condition, ready for immediate use upon arrival.

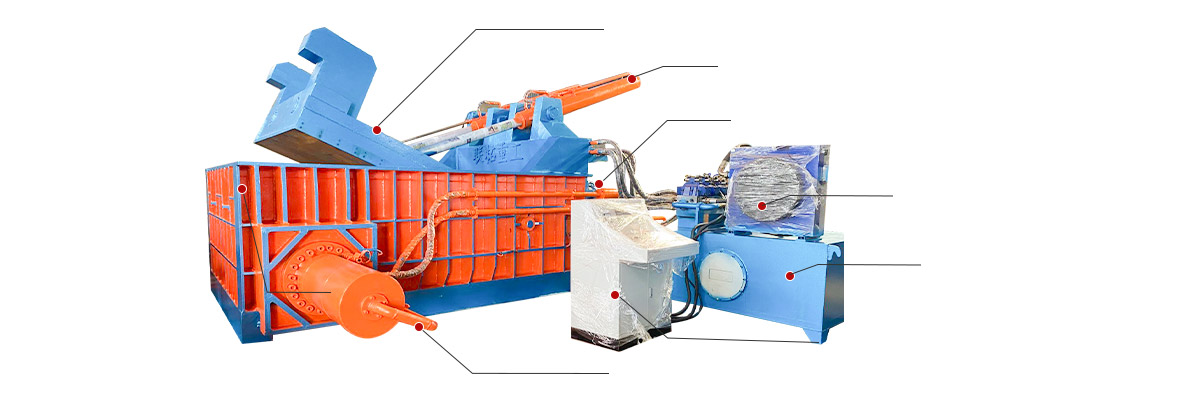

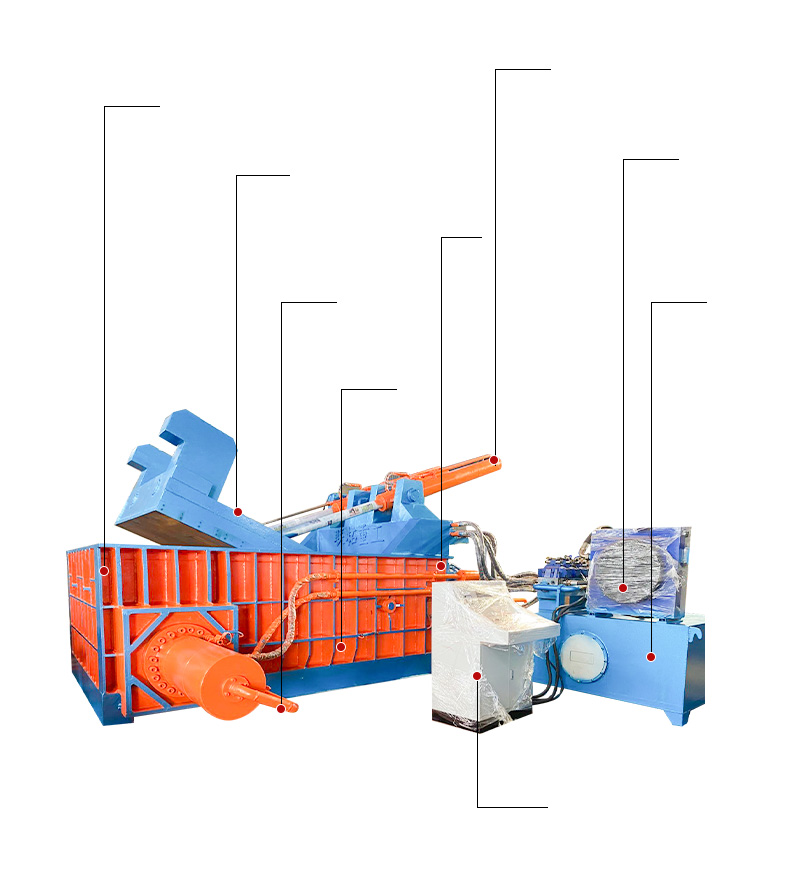

Main Parts of Hydraulic Scrap Metal Baler

- The hydraulic station, cooler, door cover, chamber, main and side cylinders, and an automated control system make up our hydraulic scrap metal baler.

Door cover

Door cylinder

Side cylinder

Cooler

Hydraulic station

Automatic control

Main cylinder

Chamber

Door cover

Door cylinder

Side cylinder

Cooler

Hydraulic station

Automatic control

Main cylinder

Chamber

Base

Door Cover

Compact the material

after feeding

Hydraulic Station

Both high and low configurations can be customized

Main Cylinder

Max pressure for

pressing material

Side Cylinder

Second time compact to

make the bale more tight

Main Features of Hydraulic Scrap Metal Baler

- Our metal baler uses Q235 iron plate and a wear-resistant inner lining like NM500 or Hardox 500. It resists impact, endures high pressure without deforming, and lasts over 10 years.

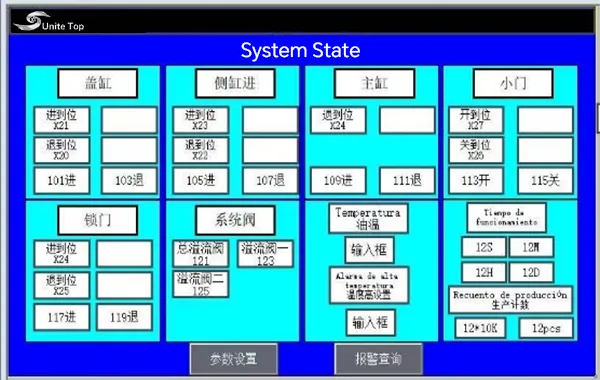

Intelligent Touch Screen

- Easy-to-use interface with real-time status monitoring

Remote Control Operation

- Supports wireless operation for convenient machine control

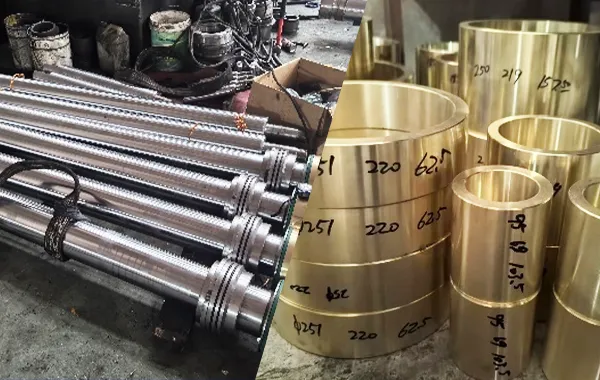

Guide Sleeve Rust-Proof Treatment

- Anti-corrosion coating ensures long-term reliable performance

Copper Sleeve Instead of Sealing Ring

- Enhances sealing performance and wear resistance

Multiple Security Protection

- Includes emergency stop and double hydraulic lock system

More than 30+ Years of Production Experience,

providing customized more than 3000+ sets scrap metal recycling schemes.

What We Can Customize

- As a professional manufacturer of custom balers, we offer complete customization services to meet diverse operational needs. Our customization options include:

- Bale Size and Shape

- We offer rectangular, square, or octagonal bales ranging from 300×300 mm to 800×800 mm, customized for transport&storage needs.

- Compression Chamber Size

- Chamber sizes range from 1200×700×600 mm to 4000×3000×1400 mm, based on scrap volume and material type.

- Bale Discharge Methods

- Choose from forward-out, side push-out, turn-over, or double main cylinder discharge methods, depending on space and weight.

- Operating Modes

- Available with manual, semi-automatic, or fully automatic PLC control, based on your automation needs.

- Hydraulic Pressure Capacity

- Nominal force ranges from 125 tons to 1500 tons, adjustable to match material density and compaction demands.

- Power Configuration

- Powered by electric motors, diesel engines, or hybrid systems, depending on energy supply and site conditions.

- Machine Orientation

- Offered in horizontal or vertical layouts with open-end or closed-end designs for various workflows and spaces.

- Optional Accessories

- Upgrade with feeding conveyors, hoppers, auto tying systems, safety enclosures, remote controls, and emergency stops for efficiency and safety.

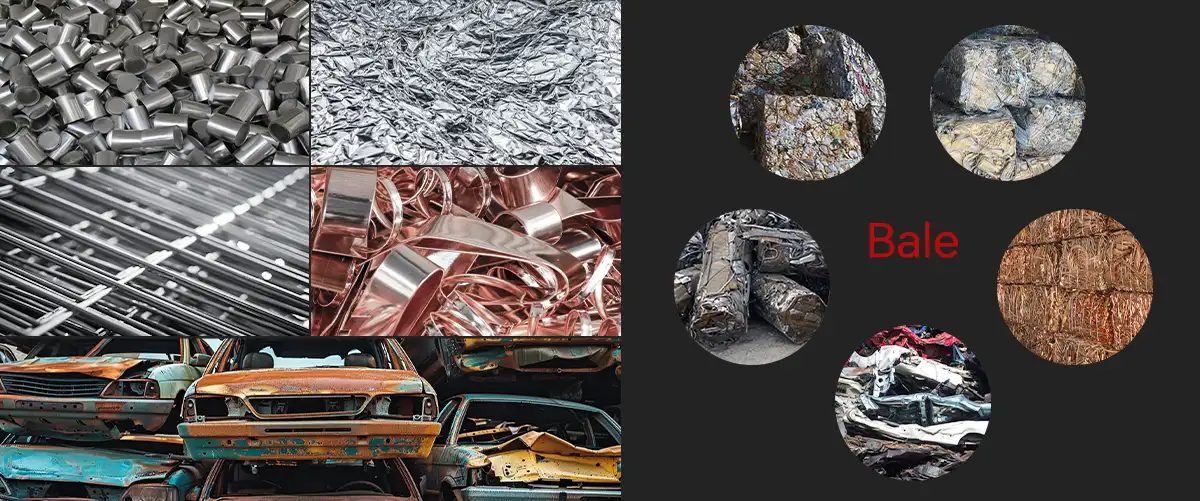

Materials We Can Process

- Our custom balers handle a wide range of ferrous, non-ferrous, and industrial scrap. Built for efficiency, durability, and flexibility, they are ideal for compressing the following materials.

- Steel Scrap: Includes sheet metal, rebar, steel turnings, and structural offcuts.

- Aluminum Scrap: Such as extrusions, beverage cans, profiles, and casting residues.

- Copper Scrap: Covers wires, tubes, bus bars, and copper turnings from manufacturing waste.

- Stainless Steel: From machining operations, fabrication shops, or dismantled equipment.

- Iron Scrap: Includes cast iron parts, machine components, and heavy industrial scrap.

- Scrap Vehicles and Auto Parts: Suitable for compacting car shells and dismantled metal components.

- Used Appliances: Compresses refrigerators, washing machines, and other scrap household goods.

- Metal Turnings and Shavings: From CNC machines, lathes, milling, and machining operations.

- Lightweight Metals: Includes aluminum foil, alloy fragments, and other thin-gauge metal packaging.

- Mixed Metal Scrap: Efficiently handles bundled or unsorted combinations of different metal types.

Our Main Metal Baler Machine

Y81-1250

- Nominal Force: 125 tons

- Chamber Size: 1200*700*600mm

- Bale Size: 300*300mm

- Power: 15KW

Y81-2000

- Nominal Force: 200 tons

- Chamber Size: 1600*1200*800mm

- Bale Size: 400*400mm

- Power: 37KW

Y81-2500A

- Nominal Force: 250 tons

- Chamber Size: 2000*1400*900mm

- Bale Size: 400*400mm

- Power: 2*22KW

Y81-3150A

- Nominal Force: 250 tons

- Chamber Size: 2500*2000*1200mm

- Bale Size: 600*600mm

- Power: 2*45KW

Y81-4000C

- Nominal Force: 400 tons

- Chamber Size: 5000*2000*1300mm

- Bale Size: 700*700mm

- Power: 3*45KW

Y81-6300A

- Nominal Force: 630 tons

- Chamber Size: 3000*2500*1400mm

- Bale Size: 700*700mm

- Power: 4*45KW