Q43 Series Hydraulic Scrap Metal Alligator Shear Machine

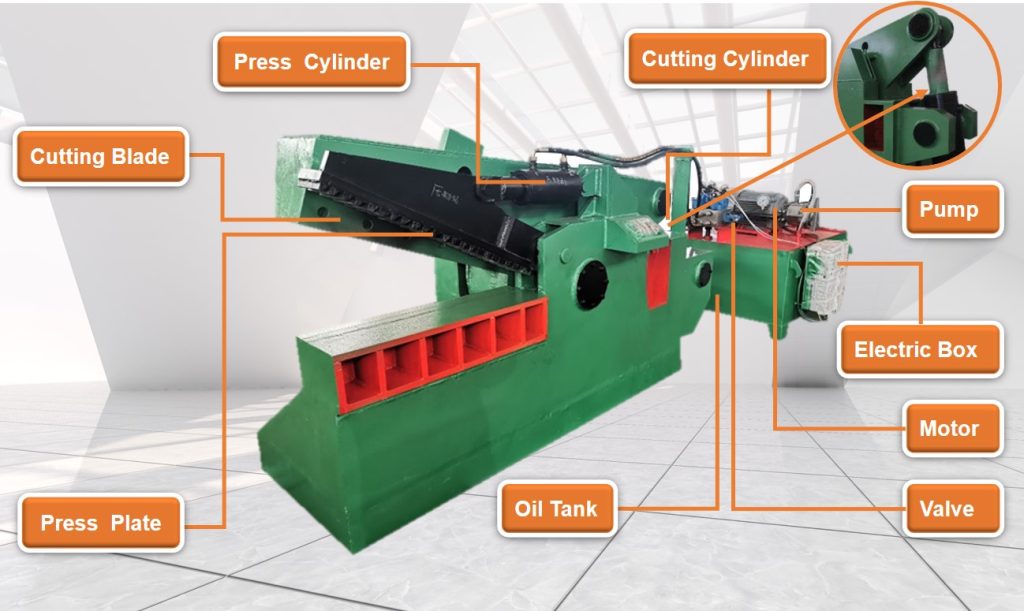

Key Components of Hydraulic Alligator Shear

The cutting blade, press plate, cylinders, motor, pump, oil tank, valve, and electric control box are all included in our hydraulic alligator shear machine.

Cutting Blade

Heavy-duty blade designed for powerful, precise metal shearing with excellent wear resistance and long operational life.

Press Plate

Secures scrap material firmly during shearing, preventing displacement and ensuring cutting stability and operator safety.

Press Cylinder

Applies downward hydraulic force to drive the press plate, firmly holding material in place before cutting.

Cutting Cylinder

Activates the cutting blade with high pressure, ensuring efficient, consistent motion for shearing various metal types.

Oil Tank

Stores and supplies hydraulic oil to the system, ensuring smooth, stable, and continuous machine performance.

Valve

Regulates direction and pressure of hydraulic fluid flow, controlling both press and cutting cylinder functions.

Motor

Drives the hydraulic pump to run the machine by converting electrical energy into mechanical power.

Electric Box

Houses the electrical control system, enabling automation, safety interlocks, and coordinated machine function.

Pump

Supplies pressurized hydraulic oil to cylinders, enabling strong, efficient shearing and pressing operations.

Key Features of Hydraulic Alligator Shear

Our hydraulic alligator shear is built with high-strength steel and a box-type welded frame, ensuring exceptional impact resistance and durability for continuous heavy-duty operations.

|

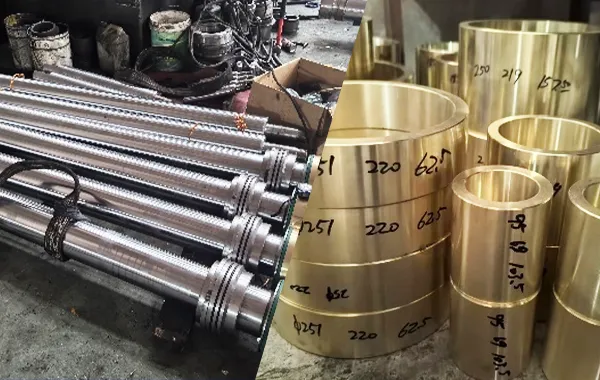

Rust-Proof Guide Sleeves

Special anti-corrosion treatment enhances long-term durability and smooth operation under harsh working conditions. |

| Copper Sleeves in Place of Sealing Rings

Upgraded with copper sleeves to significantly improve wear resistance and sealing performance, reducing maintenance frequency. |

|

|

Comprehensive Safety Protections

Integrated with manual control buttons, protective enclosures, and emergency stop switches to ensure safe and error-free operation. |

Product Specifications

|

Model |

Max Cutting Force(Ton) | Blade Length(mm) | Max Cutting Size(mm) | Shearing Frequency(times/min) |

Power(kw) |

|

Q43-630 |

63 |

600/800 |

35×35 φ40 |

10-12 |

7.5 |

|

Q43-1200 |

120 |

600/800 |

50×50 φ55 |

10-12 |

15 |

|

Q43-1600 |

160 |

700/800 |

55×55 φ63 |

8-10 |

18.5 |

|

Q43-2000 |

200 |

800/1000 |

65×65 φ70 |

8-10 |

22 |

|

Q43-2500 |

250 |

1000/1200 |

70×70 φ80 |

6-8 |

2×15 |

|

Q43-3150 |

315 |

1200 |

75×75 φ85 |

6-8 |

2×18.5 |

|

Q43-4000 |

400 |

1200/1500 |

90×90 φ100 |

4-8 |

2×22 |

|

Q43-5000 |

500 |

1600 |

100×100 φ100 |

4-8 |

2×30 |

|

Q43-6000 |

600 |

1600/1800 |

110×110 φ120 |

4-8 |

2×45 |

Applications

Hydraulic scrap metal alligator shear machines are versatile and are used in various settings due to their robust design and efficient operation.

Here are some typical applications:

- Scrap Yards: Alligator Shear machines are essential in scrap yards for cutting metal into manageable sizes before processing or shipping.

- Recycling Facilities: They help recycle by shearing metal scraps into smaller pieces, making handling and processing various metals easier.

- Automobile Dismantling: Used in the automotive industry, especially in dismantling old or damaged vehicles to separate different metal components.

- Construction Sites: These metal shear machines are useful for cutting rebar, steel beams, and other metal construction materials on-site for more straightforward disposal or recycling.

- Manufacturing Plants: They assist in cutting off excess parts and materials in manufacturing processes, helping to maintain efficiency and reduce waste.

- Metal Fabrication Shops: Employed for precise cutting of metal sheets, bars, and other forms to specific dimensions as required in custom fabrication.

- Foundries: Useful for cutting large metal pieces and scraps into smaller, furnace-ready sizes.

- Shipbreaking: Used in breaking down ships, cutting through thick metal plates and structures efficiently.

Cooperative Suppliers

Our hydraulic scrap metal alligator shear machines feature customized, high-quality components from renowned global brands. We have maintained a decade-long partnership with leading suppliers such as Siemens, NOK Omron, Schneider, Chint, and Mitsubishi, ensuring superior performance and reliability.