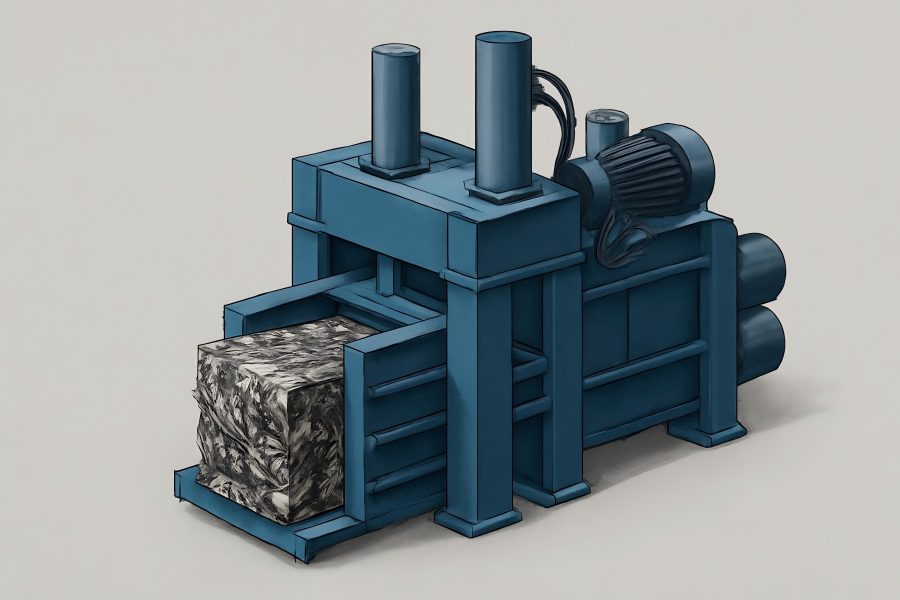

In the metal recycling industry, balers are essential for compressing scrap metal into compact, manageable bales that facilitate storage, transportation, and processing. The choice between single-plunger and dual-plunger (or two-ram) balers significantly impacts operational efficiency, maintenance costs, and overall profitability.

This comprehensive guide delves into the performance characteristics, cost implications, and suitability of each baler type to aid businesses in making informed decisions.

Understanding Baler Mechanics

Single-Plunger Balers

Single-plunger balers operate using a single hydraulic ram to compress scrap metal into bales. The process involves the ram moving forward to compress the material and then retracting to allow for the ejection of the formed bale. This design is prevalent in various industries due to its simplicity and cost-effectiveness.

Advantages:

- Lower Initial Investment: Single-plunger balers are generally more affordable, making them accessible for small to medium-sized operations.

- Simplicity: With fewer moving parts, these balers are easier to operate and maintain.

- Compact Design: Their smaller footprint is advantageous for facilities with limited space.

Disadvantages:

- Longer Cycle Times: The sequential nature of the compression and ejection processes can lead to longer cycle times, reducing throughput.

- Lower Bale Density: The compression force is applied in one direction, potentially resulting in bales with lower density, which can affect storage and transportation efficiency.

Dual-Plunger (Two-Ram) Balers

Dual-plunger balers incorporate two hydraulic rams: one for compression and another for ejection. This design increases throughput and decreases cycle times by enabling simultaneous compression and ejection. These balers are suitable for facilities that process large volumes of scrap metal or handle dense materials.

Advantages:

- Increased Throughput: The ability to perform multiple actions simultaneously leads to faster processing times.

- Higher Bale Density: Dual rams can apply more uniform compression, resulting in denser bales.

- Increased Flexibility: A greater variety of materials, even those that are more difficult to compress, can be handled by these balers.

Disadvantages:

- Higher Initial Cost: The complexity of dual-plunger systems typically comes with a higher price tag.

- Increased Maintenance: More moving components may necessitate more frequent maintenance and might result in downtime.

- Greater Footprint: The design might need more room, which smaller facilities would not be able to provide.

Performance Comparison

| Feature | Single-Plunger Balers | Dual-Plunger Balers |

| Cycle Time | Longer due to sequential operations | Shorter with simultaneous actions |

| Bale Density | Generally lower | Higher due to uniform compression |

| Throughput | Moderate | Higher due to reduced cycle times |

| Material Flexibility | Suitable for standard materials | Capable of handling diverse materials |

| Space Requirements | Compact | Requires more space |

Cost Analysis

Initial Investment

- Single-Plunger Balers: Typically range from $50,000 to $150,000, depending on capacity and features.

- Dual-Plunger Balers: Generally priced between $150,000 and $300,000, reflecting their advanced capabilities.

Operating Costs

- Single-Plunger Balers: Lower energy consumption due to simpler mechanics. Maintenance costs are moderate, with fewer components subject to wear.

- Dual-Plunger Balers: Higher energy consumption and maintenance costs due to the complexity of dual hydraulic systems and additional components.

Return on Investment (ROI)

While dual-plunger metal balers have a higher upfront cost, their increased throughput and higher bale density can lead to a quicker ROI. The enhanced efficiency can result in cost savings in labor and transportation, offsetting the initial investment over time.

Applications and Suitability

- Single-Plunger Balers: Ideal for operations with steady, moderate volumes of recyclable metals. Their simplicity and cost-effectiveness make them suitable for small to medium-sized facilities.

- Dual-Plunger Balers: Best suited for high-volume operations requiring rapid processing and handling of diverse materials. The investment in dual-plunger technology is justified in large-scale recycling centers where efficiency and throughput are paramount.

Conclusion

The choice between single-plunger and dual-plunger balers hinges on specific operational needs, budget constraints, and long-term goals. Single-plunger balers offer a cost-effective solution for smaller operations, while dual-plunger balers provide enhanced efficiency and throughput for larger facilities.