In the recycling and metal fabrication industries, the efficiency of scrap processing significantly influences operational success. Hydraulic scrap shears are pivotal in this process, offering robust solutions for cutting metal into manageable sizes.

This post compares two prevalent types of hydraulic scrap shears: the Alligator Hydraulic Scrap Shear and the Hydraulic Guillotine Scrap Shear.

Definition and Basic Mechanics

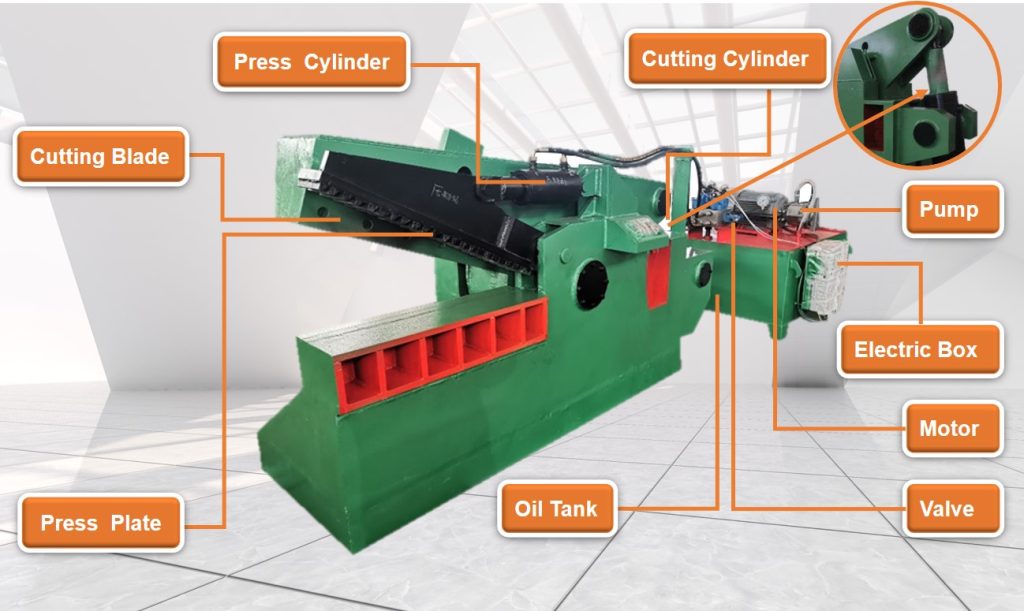

Alligator Hydraulic Scrap Shear

Definition: Alligator hydraulic scrap shears are named for their distinctive, hinged jaw-like appearance miming an alligator’s mouth. These shears are designed to handle harsh, mixed, and oversized scrap materials.

Basic Mechanics: These shears operate on a simple mechanical principle where a hydraulic cylinder powers the movement of one of the jaws while the other remains stationary. When the hydraulic pressure is applied, the moving jaw descends onto the scrap material between the jaws, effectively cutting it through shear force. This design is particularly effective for processing irregular shapes and sizes, allowing operators to quickly and easily segment scrap into manageable pieces.

Hydraulic Guillotine Scrap Shear

Definition: Hydraulic guillotine scrap shears feature a straight blade that moves vertically up and down, much like a guillotine. This design is suited for making clean, straight cuts and can handle high volumes of scrap, mainly flat sheet materials.

Basic Mechanics: In hydraulic guillotine shears, the blade is mounted on a ram and is powered by hydraulic cylinders. As the cylinders activate, the blade descends across a fixed edge or bed, shearing the material cleanly and efficiently. This shear type can process larger and thicker materials with greater precision than alligator shears, making it ideal for operations requiring uniform cuts and repetitive actions.

Technical Specifications

| Specification | Alligator Hydraulic Scrap Shear | Hydraulic Guillotine Scrap Shear |

|---|---|---|

| Size and Capacity | Petite to large models; cuts up to a foot thick. | Larger, more robust; cuts several inches thick. |

| Blade Configuration | Replaceable high-strength steel, for varied scrap. | Straight, adjustable for uniform cuts. |

| Hydraulic System | High force, variable pressure. | Precision control, programmable settings. |

| Operational Efficiency | Quick for irregular scrap; less energy-efficient. | Precise and clean cuts; more energy-efficient. |

Performance and Efficiency

Cutting Capacity and Material Handling

- Alligator Hydraulic Scrap Shear: Best suited for scrapyards and recycling centers where varied and irregular scrap materials are common. These shears excel in quickly breaking down large pieces into smaller, more manageable sizes, although the cuts may not be as clean or precise.

- Hydraulic Guillotine Scrap Shear: Ideal for processing flat sheets and uniform materials in manufacturing and industrial settings. The clean, straight cuts are perfect for preparing metal for further processing and fabrication, where precision is crucial.

Operational Efficiency

- Alligator Hydraulic Scrap Shear: Generally faster in cutting cycle times when dealing with mixed scrap. This speed comes at the expense of energy efficiency, as more power may be required to handle more rigid materials.

- Hydraulic Guillotine Scrap Shear: Offers a slower, more deliberate cutting action, which is more energy-efficient. The precise control over the cutting process reduces waste and can decrease operational costs over time.

Application Suitability

Alligator Hydraulic Scrap Shear

- Ideal Use Cases: Best for scrapyards and recycling where diverse, oversized scrap is common. Efficient for rapid breakdown of bulky items like old cars and appliances.

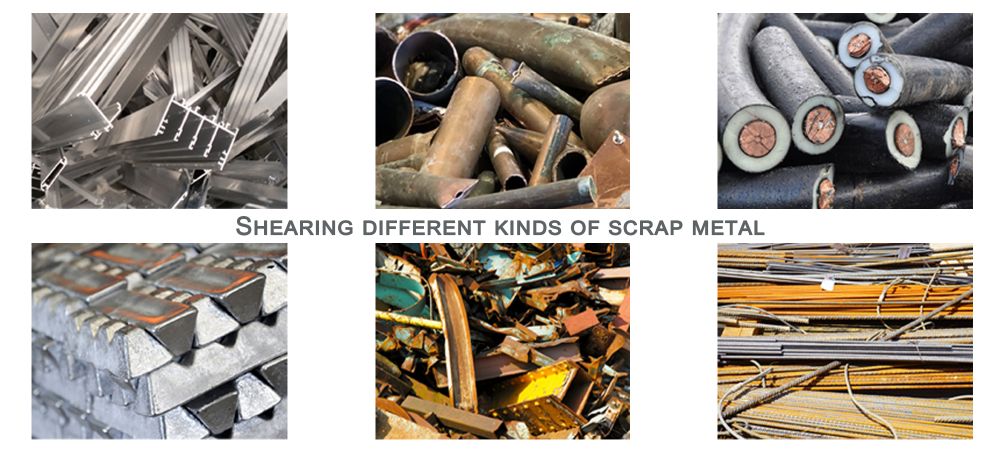

- Material Types: Handles ferrous and non-ferrous metals effectively, such as steel, aluminum, and copper.

- Advantages: Excellently manages rugged and irregular materials, streamlining the processing and transport of scrap.

Hydraulic Guillotine Scrap Shear

- Ideal Use Cases: Ideal for metal fabrication industries needing clean, precise cuts for uniform metal sheets.

- Material Types: Suitable for sheet metal and thicker metal plates, both ferrous and non-ferrous.

- Advantages: Delivers high-precision cuts crucial for manufacturing, ensuring materials are prepared for further processing with minimal waste.

Safety and Operational Features

Alligator Hydraulic Scrap Shear

- Safety Features: Usually equipped with blade protection devices and emergency stop mechanisms to protect operators. The design also reduces the risk of flying debris during cutting.

- Operational Features: Simple to operate, with manual controls or semi-automatic options. It is durable and requires minimal training for operators.

Hydraulic Guillotine Scrap Shear

- Safety Features: It has safety guards, light curtains, and laser cutting lines to enhance visibility and safety. It often includes programmable features that ensure consistent operation while minimizing operator interaction with the blade.

- Operational Features: Features high-level control systems for precise cuts, often fully automatic, to increase throughput and reduce labor.

Maintenance and Durability

Alligator Hydraulic Scrap Shear

- Maintenance: Regular hydraulic systems and blade sharpening maintenance is required to ensure efficient operation. The rugged design is relatively easy to maintain under harsh conditions.

- Durability: Built to withstand heavy use, especially in rugged environments like scrapyards. The robust construction helps extend the life of the shear.

Hydraulic Guillotine Scrap Shear

- Maintenance: More complex due to its precision components. Regular calibration and maintenance are necessary to maintain the system’s smooth operation.

- Durability: Designed for longevity but may require more frequent maintenance checks to manage wear and tear due to precision cutting processes.

Cost Analysis

Alligator Hydraulic Scrap Shear

- Initial Investment: Generally less expensive than hydraulic guillotine shears due to more straightforward mechanics and less precise cutting capabilities. Costs vary based on size and capacity.

- Running Costs: While typically lower in energy consumption, these shears may incur higher maintenance costs over time due to the rugged nature of the materials they handle.

|

|

Hydraulic Guillotine Scrap Shear

- Initial Investment: Higher due to more sophisticated design and precision cutting technology. The cost increases with the size and performance of the machine.

- Running Costs: More energy-efficient in operations that require continuous, precise cuts. However, the precision components may lead to higher maintenance expenses and more specialized labor.

-

Provides high precision and consistency in cuts.

-

Suitable for high-volume cutting tasks.

-

Energy-efficient and potentially lower operational costs.

-

Higher initial investment.

-

Requires more complex maintenance and skilled operators.

-

Conclusion

Choosing between an Alligator Hydraulic Scrap Shear and a Hydraulic Guillotine Scrap Shear depends on the operation’s specific needs. Alligator shears are ideal for scrapyards and recycling centers where precision is less critical than throughput.

In contrast, guillotine shears are better suited for manufacturing environments where high precision and volume are essential. The decision should be guided by considering both the immediate and long-term financial implications, as well as the operational requirements and goals of the facility.